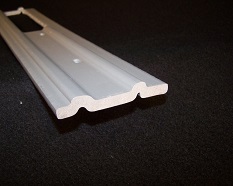

Custom Foam Profiles for Thermoplastic Extrusions

Crescent Plastics has extensive experience in developing foamed plastics for thermoplastic extrusion applications. We have developed a process to produce lightweight, high strength custom extrusions from foam using various extrusion materials—including HIPS, ABS, PVC, HDPE, and reprocessed foam plastic materials. With a density similar to wood, parts produced from this thermoplastic extrusion process can be given a wood grain appearance and used as an effective, low-cost wood replacement.

Request a quote or contact Crescent Plastics to discuss customized foam profiles and extrusions for your project.

Applications for Thermoplastic Extrusions

Our custom foam profiles for thermoplastic extrusions are perfect for applications that require lightweight parts with strength and durability, such as point of purchase displays, molding, frames, and structural members. Using foamed plastic parts for thermoplastic extrusion applications can provide product enhancement at an affordable cost. Our experts will guide you through the process of creating customized foam profiles and plastic extrusion shapes and answer any questions that may help facilitate your needs.

Foamed Plastic Part Applications

- Building & architecture

- Concrete forms & structural members

- Edge protectors

- Fascia plate

- Fascia panel

- Wood replacement

- Picture frames for home or commercial

- POP (point of purchase) fixtures & displays

- and many, many others

Advantages of Foamed Plastic Extrusion Shapes

- Lighter & less expensive than standard thermoplastic extrusion

- Can be used to reduce material content, saving you money

- Excellent replacement for wood products

- Can be cut or routed like wood products

- Lighter weight than wood products

- Unlike wood, rigid foam will not rot

Benefits of Custom Extrusions Made from Rigid PVC Foam

- UV resistant

- Self-extinguishing

- Accept fasteners well

- Easily glued

- Can be curved & shaped utilizing heat

- Insect & animal resistant

Personalized Extrusions Made to Your Specifications

Crescent Plastics provides personalized extrusions, and plastic extrusion shapes made to your specifications. We offer no “stock” or “off the shelf” products—everything we do is custom. If you need custom-made foam profiles, we can meet your needs with efficient, high volume thermoplastic extrusion processes.

Contact Us for Custom Foam Profiles & More

Crescent Plastics has over 65 years of design and production experience and have proven ourselves as innovators in the field of thermoplastic extrusion. Request a quote or contact us for the custom foam profiles you need.