Custom Extrusions for Appliance Products

Crescent Plastics has been producing custom extrusions for appliance manufacturers for more than 60 years. We extrude a wide variety of appliance products including pan trims, door trims, wire raceways, ductwork, non-magnetic gaskets, bumpers, light lenses, breaker strips, and polypropylene and polyethylene tubing.

Appliance Product Extrusion Services

We have the know-how and the expertise to deliver custom extrusions in various geometries, from 0.188" diameter tubing and larger, up to 20" wide profiles. We have complete coextrusion capabilities, which enable us to create custom extrusions from two or more different materials.

We can produce custom extrusions for your appliances from a wide variety of thermoplastic materials, including ABS, HIPS, PVC, PE, PP, and Acrylic(PMMA). We also have the ability to extrude engineered thermoplastics including Polycarbonate(PC), Ultem® (PEI), Polysulfone(PSU), Polyurethane(PU), and Noryl®(PPO).

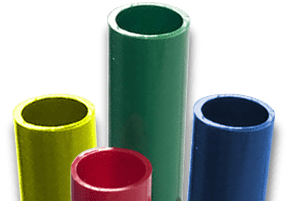

Polyethylene Tubing

Fabrication Capabilities for Custom Extrusions

With on-line and off-line fabrication capabilities, Crescent Plastics can provide value-added services to help you achieve the lowest cost with enhanced functionality. In addition, our extensive fabrication area allows us to decorate plastics with inkjet printing, pad printing, or heat transfer to provide aesthetically appealing custom extrusions. Recycle codes code can be added, along with part identification for lot traceability. We also utilize UL flame retardant extruded plastic, along with FDA, NSF, RoHS, and WEEE compliant materials.

Contact Us for Your Appliance Manufacturing Needs.

We welcome the opportunity to review your most demanding challenges and to help turn your designs into precision custom extrusions for your appliances. Request a quote or contact Crescent Plastics for the cost-effective solutions you need