LED Lighting Diffuser Extrusions

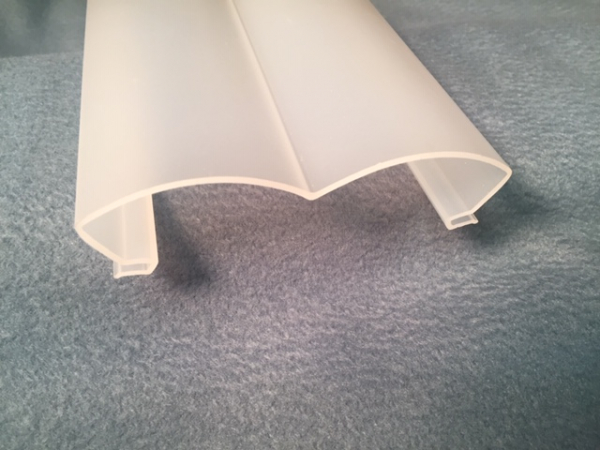

Custom manufactured extruded plastic lighting lenses add unique style and elegance to any lighting project. Crescent Plastics can help you choose the right materials, the right level of diffusion, light transmission, and assist in eliminating pixelization problems based on your project’s exclusive specifications.

For over 70 years, Crescent Plastics has been extruding acrylic light diffusers for lighting applications. The lighting industry has recently begun to transition into more energy-efficient LED fixtures, and we are part of this technology trend. We’ve been working with material suppliers and our customers to develop specific formulations for use in improved acrylic and polycarbonate extrusions, extruded LED lenses, LED light diffuser acrylic lenses, LED light lens covers, reflectors, and dust covers.

Contact us for more information regarding our custom plastic extrusion options or call us at 812-428-9305 and we will gladly assist you with your specific questions. Crescent Plastics is your trusted source for custom standard and LED lighting extrusion and diffuser products.

What are Custom Lighting Lens Extrusions?

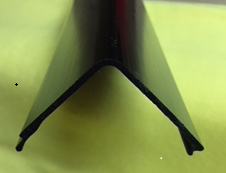

Extruded plastic lighting lenses easily install to either the bottom or side of a light fixture and are manufactured in clear and diffused options. Lighting extrusions provide beneficial light spreading and scattering benefits, while protecting lighting fixtures from dust, helping to conserve energy by providing more even lighting that reduces the need for additional fixtures.

Crescent Plastics works with you to provide the right light transmission, eliminate shadows, reduce or eliminate pixelization, and optimize cost.

Custom Lighting Diffuser Options

Extruded plastic lighting lenses are manufactured in lay-in, snap-in, clip-on, and other options to fit virtually any type of lighting. Common types of diffuser panels and plastic lighting lenses include:

- Light diffusers and lenses

- Display light covers

- Architectural Lighting

- Outdoor lighting lenses

- Low Bay lenses

- High Bay lenses

- Industrial lenses

- Retail lenses

- Commercial lenses

- Recessed lenses

- Surface mount lenses

- Refrigerated display lenses

LED Light Diffuser Lenses

With our extensive materials knowledge and extrusion experience, Crescent Plastics can help you choose the right level of diffusion for your extruded LED lens and LED light diffuser acrylic or polycarbonate lens profiles.

We provide unmatched design support for numerous applications, including considerations for material blend, diffusion, efficacy, aesthetics, fit, and cost. We offer quick turnaround times on tooling projects.

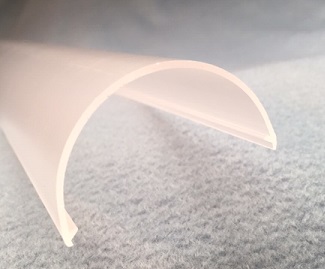

Crescent manufactures custom polycarbonate extrusions and acrylic extrusions with different levels of frost and diffusion from 50% to 95% light transmission. to provide the proper light transmission and hiding power for your extruded LED lenses. For additional “special effects,” we can also supply co-extruded LED lenses combining different colors or levels of diffusion.

Polycarbonate Diffusers vs Acrylic Lighting Reflectors

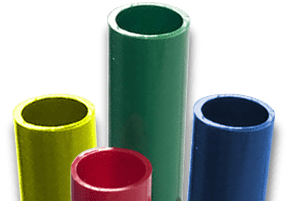

Polycarbonate diffusers and acrylic light diffusers are perhaps the most common types of diffuser lenses, though other materials, such as PVC may also be used. Extruded plastic lighting lenses come in a variety of shapes ranging from flat to contoured covers. Our custom-made lighting diffusers are manufactured in over 50+ frosted or clear extruded acrylic and can have colors, frost and texturing (such as ribbing and prismatic patterns), or films added to create a customized look.

For more information on the differences between polycarbonate and acrylic light diffusers, view our acrylic and polycarbonate lighting fixture lens page to learn more.

Acrylic LED Extruded Lens

Our custom extrusions are the perfect solution for LED acrylic light diffuser lenses. At Crescent, we can provide extruded frosted acrylic lenses for any lighting application. Benefits of acrylic include durability, flexibility, and UV resistance.

Crescent Plastics manufactures acrylic lenses in several blends to provide the right amount of diffusion. New unfrosted and frosted LED light diffuser acrylic lenses provide diffusion levels from 50% to 95% light transmission for resolving pixelation issues.

Polycarbonate Extrusion Light Diffuser

Polycarbonate is popular for a variety of applications thanks to its great versatility. Polycarbonate extrusions exhibit high impact resistance, stiffness, moisture resistance, and heat resistance. At Crescent Plastics, we have years of experience producing polycarbonate extrusions, such as frosted polycarbonate lenses and diffused polycarbonate lenses, all designed specifically for LED light fixtures.

We extrude fabricated clear polycarbonate extrusions in flame retardant (FR) grades which meets UL 94V-0 specifications at 1mm (0.040”) thickness. These polycarbonate materials are available in several different diffusion levels, ranging from clear at 91.5% light transmission to diffused with 63.7% light transmission at 1 mm thickness.

PVC Lighting Extrusions

If your application requires chemical resistance, PVC may be the material of choice for your diffuser. At .060” thick frosted PVC is available in three different grades of 63%, 76%, and 78% light transmission. The notched izod is slightly higher than a non-impact modified acrylic and a UL flammability rating of 5VA at .060” can be achieved. Let Crescent Plastics help you with your diffuser lens.

Custom Acrylic & Polycarbonate Lens Extrusion for Your Application

Crescent Plastics’ in-house tooling facility allows us to build all plastic extrusion and punch dies internally, which ensures optimum quality, timing, and cost minimization. Crescent is ISO 9001:2015 certified and offers acrylic and polycarbonate extrusions that are made to standards that exceed our competitors’ similar extruded products.

We can help reduce your costs by blending in color concentrates to find the right amount of diffusion at the right price for your extruded LED lens application. Different levels of diffusion can eliminate the need for costly coatings or Mylar inlays, which will save you money.

We also work with reflective acrylic and extruded polycarbonate materials. Benefits of these materials include:

- ≈97% reflective surface

- Replaces expensive reflective film and coatings

- Improves lighting efficiency and design

We can also enhance the reflectivity of your extruded LED lens by applying foil materials to your profile.

Design Assistance for Plastic Lighting Dust Covers

Our experienced engineers can assist your team at any stage of your product’s development. Crescent Plastics can assist you in developing a prototype for an extruded LED light diffuser and provide speed to market for moving into production.

For more involved projects, our engineers can take your rough sketch or blueprint and join forces with your team to create the best design possible. We also provide 3D printed samples that allow for review of fit and assembly ergonomics. Our use of DFM methodology and our expertise in acrylic and polycarbonate extrusion ensure optimized quality and production economics for your LED light diffuser project.

Cost-Saving Strategies for Lighting Lens Extrusion

We build all our extrusion dies and downstream tooling in-house, minimizing costs and saving time for our customers. Moreover, DFM methodologies optimize efficiency, which helps our customers get their extruded LED light diffuser products to market sooner, which increases company revenue.

State-of-the-Art Technology for Acrylic Light Diffusers

Light diffusion and transmission are two of Crescent Plastic’s strongest assets. Our engineers have the experience and knowledge to ensure that every extruded LED lens cover we produce allows the end-user to create the ambiance or lighting scheme that they desire.

Our use of online cutting technology enables us to hold tighter tolerances than traditional methods can, providing a more precise extruded plastic lighting lenses and diffuser panels.

Contact Crescent Plastics for Custom Lighting Extrusions Today

Contact us for more information regarding our custom standard and LED lighting extrusion and diffuser options, or request a quote for further pricing details today. Crescent Plastics offers light fixture lenses for a wide range of applications. We provide full design support and ensure quality and consistency by building all extrusion and punch dies in our in-house tooling facility.